Key Steps in Creating a Custom Foot Orthotic Prescription

To get a truly custom made foot orthotic a number of steps must be followed to formulate the prescription that will address your foot complaint.

History of the injury

The process begins with a history of you foot or lower leg complaint. You will be asked to explain the problem in your own words. The goal is to establish how your complaint progressed to this stage. Some of the information discussed may direct your biomechanical examination towards specific tests as well as having an impact on the prescription of the custom foot orthotic.

Biomechanical examination

Biomechanical examination

The biomechanical examination of your feet and lower extremities will be evaluated while you either are standing or lying on a examination table. The motion of joints and the alignment of the bone segments of the foot and lower legs will be evaluated. Certain complaints will direct the evaluation to specific foot or lower leg muscles that may be tight or weak. The biomechanical examination will determine if there is boney malalignment within the foot or between the foot and lower leg. Thesei malalignments can cause an overuse stress on a muscles, tendons or ligaments. Overuse stress will cause tissue damage leading to pain or instability.

Gait Analysis

Gait Analysis

During your evaluation for a custom foot orthotic you will be asked to walk. The findings of the biomechanical examination will be either confirmed or further biomechanical testing will be required. Gait analysis may demonstrate if you have one leg shorter than the other or if you have one foot that is flatter than the other foot. More advanced gait analysis may include in-shoe pressure measurement that helps in the prescription of the CFO. If you are a runner, you may be required to run on a tread mill with 2 to 4 cameras filming you as you run.

3 Dimensional Plaster Casting

3 Dimensional Plaster Casting

Plaster casting is used to capture the exact 3 dimensional contours of the foot. Plaster casting is skill that is perfected with practice. There are a number of ways to capture 3D contours of your foot. The casting method that is used to capture the foot contours is determined by the flexibility in the joints of your foot.

Semi-weight bearing casting

If your foot does not have much joint motion due to arthritis your foot will be casted using a semi-weight bearing cast method. The semi-weight bearing cast is taken while you are in a sitting position with your foot in contact with the floor. Once the plaster is placed on the foot your knee and ankle will be placed in a 90 degree joint positions. Semi weight bearing casts are sometimes captured with a foam box.

Neutral position casting

If your foot has no joint restrictions due to arthritis your foot will be casted in the non weight bearing neutral position cast method. The neutral position cast is taken in a non weight bearing position while you are lying on a examination table. During the casting, your foot is held in a position that approximates mid foot joint stability. The talo-navicular joint is the keystone for foot stability.

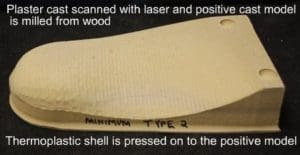

3 dimensional laser scanner

Casting can also be performed using a laser scanner. A 3 dimensional laser scanner uses at least 2 lasers and 2 cameras to capture all the anatomical contours of the plantar aspect of the foot just like a plaster cast. Using a laser scanner does have some advantages. There is no messy plaster applied to your foot and the cast information can be sent electronically to the orthotic laboratory.

Prescription writing

The custom foot orthotic that is dispensed and fitted in to your shoe is not just a piece of plastic. The combination of information from the history, biomechanical examination, gait analysis, and most importantly a skilled 3D casting of the foot will provide the necessary elements for the prescription of the the custom foot orthotic. The written custom foot orthotic prescription is a thoughful process using all of the information gained from the history, biomechanical exam and gait analysis. The following components have to be considered when your custom foot orthotic prescription:

- The flexibility of the shell material is based on your weight, activity or occupational demands. The thicker the material the more stability.

- The width of the device. The wider the device the more stability

- The depth of the heel cup. The deeper the heel cup the more stability

- There are a number of additions that can be added on to the shell to accommodate problems such as a neuroma or corn.

- If you require a more motion controlling or stabilizing custom foot orthotic it will usually take up more room inside the shoe. Footwear advice is a very important aspect of custom foot orthotic therapy. Some prescribed custom foot orthotics will not fit in every shoe.

Orthotic Fabrication

The prescription and the cast are sent to an orthotic lab for custom foot orthotic fabrication. The process from evaluation and casting to dispensing can take up to 2 weeks to complete.

Orthotic dispensing

The finished custom foot orthotic is dispensed to you using a checklist as well as advice on the break in period. The break in period may take about 4 weeks for you to feel comfortable. Some people can adapt to a custom foot orthotic immediately while other people need more time to adjust. The body needs time to adjust. You may notice mild aches when you first begin wearing orthoses. This discomfort may occur in your feet, ankles, legs, hips or back. This discomfort will disappear as you adjust to your custom foot orthotics.

Follow up custom foot orthotic modifications are expected in some cases. There might be a need for modification or adjustment of your custom foot orthotic to make them more comfortable. This is usually not recommended until you have worn them for 4 weeks.

Book an Appointment

Book an appointment for custom foot orthotic assessment.

Biomechanical examination

Biomechanical examination Gait Analysis

Gait Analysis 3 Dimensional Plaster Casting

3 Dimensional Plaster Casting